86-021-54422420 13818829143

86-021-54422402 17701898099

86-021-54422420 13818829143

86-021-54422402 17701898099

链轮:带嵌齿式扣链齿的轮子,用以与节链环或缆索上节距准确的块体相啮合一种实心或带辐条的齿轮,与(滚子)链啮合以传递运动。

链轮的特性:可适合长时间大扭力下工作,传递性能稳定。易安装,好维护和方便润滑。

链轮的应用:被广泛应用于化工、纺织机械、食品加工、仪表仪器、石油等行业的机械传动等。

| 美标40系列链轮 | 美标50系列链轮 | |||||||||||||||

| 节距(Pitch)=12.7(mm) | 节距(Pitch)=15.875(mm) | |||||||||||||||

| 齿数Teeth | 外径O.D | 节径P.D | B型凸台Hub | 最大孔径 | 重量 W.t | 齿数Teeth | 外径O.D | 节径P.D | B型凸台Hub | 最大孔径 | 重量 W.t | |||||

| 毂径H | 轮厚L | Bore Max | B型. Kg | A型. Kg | 毂径H | 轮厚L | Bore Max | B型. Kg | A型. Kg | |||||||

| 8 | 38 | 33.19 | 24 | 22 | 10.5 | 0.06 | 0.30 | 8 | 48 | 41.48 | 22 | 25 | 13.5 | 0.12 | 0.12 | |

| 9 | 42 | 37.13 | 28 | 22 | 16 | 0.11 | 0.40 | 9 | 53 | 46.42 | 34 | 25 | 18 | 0.20 | 0.13 | |

| 10 | 46 | 41.1 | 32 | 22 | 18 | 0.14 | 0.05 | 10 | 58 | 51.37 | 40 | 25 | 22 | 0.27 | 0.14 | |

| 11 | 51 | 45.08 | 36 | 22 | 20 | 0.19 | 0.09 | 11 | 64 | 56.35 | 45.5 | 25 | 28 | 0.33 | 0.17 | |

| 12 | 55 | 49.07 | 40 | 22 | 22 | 0.22 | 0.10 | 12 | 69 | 61.34 | 50 | 25 | 30 | 0.41 | 0.20 | |

| 13 | 59 | 53.07 | 37 | 22 | 20 | 0.23 | 0.12 | 13 | 74 | 66.34 | 51 | 25 | 32 | 0.46 | 0.23 | |

| 14 | 63 | 57.07 | 42 | 22 | 25 | 0.28 | 0.14 | 14 | 79 | 71.34 | 52 | 25 | 32 | 0.52 | 0.27 | |

| 15 | 67 | 61.08 | 46 | 22 | 28 | 0.34 | 0.16 | 15 | 84 | 76.35 | 57 | 25 | 35 | 0.62 | 0.30 | |

| 16 | 71 | 65.1 | 50 | 22 | 30 | 0.40 | 0.18 | 16 | 89 | 81.37 | 62 | 25 | 40 | 0.72 | 0.35 | |

| 17 | 76 | 69.12 | 54 | 22 | 32 | 0.46 | 0.20 | 17 | 94 | 86.39 | 67 | 25 | 45 | 0.83 | 0.40 | |

| 18 | 80 | 73.14 | 57 | 22 | 35 | 0.51 | 0.23 | 18 | 100 | 91.42 | 72 | 28 | 48 | 1.00 | 0.45 | |

| 19 | 84 | 77.16 | 62 | 22 | 40 | 0.59 | 0.24 | 19 | 105 | 96.45 | 73 | 28 | 48 | 1.10 | 0.48 | |

| 20 | 88 | 81.18 | 67 | 25 | 45 | 0.76 | 0.29 | 20 | 110 | 101.48 | 73 | 28 | 48 | 1.20 | 0.50 | |

| 21 | 92 | 85.21 | 71 | 25 | 48 | 0.85 | 0.30 | 21 | 115 | 106.51 | 73 | 28 | 48 | 1.20 | 0.60 | |

| 22 | 96 | 89.24 | 75 | 25 | 51 | 0.95 | 0.35 | 22 | 120 | 111.55 | 73 | 28 | 48 | 1.30 | 0.66 | |

| 23 | 100 | 93.27 | 77 | 25 | 51 | 1.00 | 0.38 | 23 | 125 | 116.58 | 73 | 28 | 48 | 1.30 | 0.72 | |

| 24 | 104 | 97.3 | 63 | 25 | 42 | 0.84 | 0.40 | 24 | 130 | 121.62 | 73 | 28 | 48 | 1.40 | 0.78 | |

| 25 | 108 | 101.33 | 63 | 25 | 42 | 0.88 | 0.45 | 25 | 135 | 126.66 | 73 | 28 | 48 | 1.50 | 0.85 | |

| 26 | 112 | 105.36 | 63 | 25 | 42 | 0.92 | 0.49 | 26 | 140 | 131.7 | 73 | 28 | 48 | 1.50 | 0.90 | |

| 27 | 116 | 109.4 | 63 | 25 | 42 | 0.96 | 0.50 | 27 | 145 | 136.74 | 73 | 28 | 48 | 1.50 | 1.00 | |

| 28 | 120 | 113.43 | 63 | 25 | 42 | 1.00 | 0.56 | 28 | 150 | 141.79 | 73 | 28 | 48 | 1.60 | 1.05 | |

| 29 | 124 | 117.46 | 63 | 25 | 42 | 1.00 | 0.60 | 29 | 155 | 146.83 | 73 | 28 | 48 | 1.70 | 1.12 | |

| 30 | 128 | 121.5 | 63 | 25 | 42 | 1.10 | 0.63 | 30 | 161 | 151.87 | 73 | 28 | 48 | 1.80 | 1.20 | |

| 31 | 133 | 125.53 | 68 | 28 | 45 | 1.20 | 0.65 | 31 | 166 | 156.92 | 73 | 28 | 48 | 1.85 | 1.30 | |

| 32 | 137 | 129.57 | 68 | 28 | 45 | 1.30 | 0.70 | 32 | 171 | 161.96 | 73 | 28 | 48 | 1.90 | 1.35 | |

| 33 | 141 | 133.61 | 68 | 28 | 45 | 1.30 | 0.75 | 33 | 176 | 167.01 | 73 | 28 | 48 | 2.00 | 1.45 | |

| 34 | 145 | 137.64 | 68 | 28 | 45 | 1.30 | 0.80 | 34 | 181 | 172.05 | 73 | 28 | 48 | 2.10 | 1.55 | |

| 35 | 149 | 141.68 | 68 | 28 | 45 | 1.40 | 0.85 | 35 | 186 | 177.1 | 73 | 28 | 48 | 2.20 | 1.65 | |

| 36 | 153 | 145.72 | 68 | 28 | 45 | 1.50 | 0.90 | 36 | 191 | 182.14 | 83 | 35 | 55 | 2.85 | 1.75 | |

| 38 | 161 | 153.79 | 68 | 28 | 45 | 1.60 | 1.00 | 37 | 196 | 187.19 | 83 | 35 | 55 | 2.95 | 1.85 | |

| 39 | 165 | 157.83 | 68 | 28 | 45 | 1.65 | 1.15 | 38 | 201 | 192.24 | 83 | 35 | 55 | 3.05 | 1.95 | |

| 40 | 169 | 161.87 | 68 | 28 | 45 | 1.70 | 1.20 | 39 | 206 | 197.29 | 83 | 35 | 55 | 3.15 | 2.05 | |

| 41 | 173 | 165.91 | 73 | 32 | 48 | 2.00 | 1.20 | 40 | 211 | 202.33 | 83 | 35 | 55 | 3.25 | 2.15 | |

| 42 | 177 | 169.95 | 73 | 32 | 48 | 2.05 | 1.25 | 41 | 216 | 207.38 | 83 | 35 | 55 | 3.40 | 2.25 | |

| 43 | 181 | 173.98 | 73 | 32 | 48 | 2.10 | 1.30 | 42 | 221 | 212.43 | 83 | 35 | 55 | 3.50 | 2.40 | |

| 44 | 185 | 178.02 | 73 | 32 | 48 | 2.17 | 1.35 | 44 | 231 | 222.53 | 83 | 35 | 55 | 3.70 | 2.60 | |

| 45 | 189 | 182.06 | 73 | 32 | 48 | 2.25 | 1.40 | 45 | 237 | 227.58 | 83 | 35 | 55 | 3.85 | 2.70 | |

| 48 | 201 | 194.18 | 73 | 32 | 48 | 2.45 | 1.63 | 48 | 252 | 242.73 | 83 | 35 | 55 | 4.20 | 3.10 | |

| 49 | 205 | 198.22 | 73 | 32 | 48 | 2.51 | 1.73 | 49 | 257 | 247.78 | 83 | 35 | 55 | 4.35 | 3.27 | |

| 50 | 209 | 202.26 | 73 | 32 | 48 | 2.60 | 1.80 | 50 | 262 | 252.83 | 83 | 35 | 55 | 4.50 | 3.40 | |

| 51 | 214 | 206.3 | 73 | 32 | 48 | 2.65 | 1.88 | 54 | 282 | 273.02 | 83 | 35 | 55 | 5.05 | 3.95 | |

| 52 | 218 | 210.34 | 73 | 32 | 48 | 2.72 | 1.93 | 60 | 312 | 303.33 | 83 | 35 | 55 | 6.00 | 4.90 | |

| 53 | 222 | 214.38 | 73 | 32 | 48 | 2.80 | 1.98 | 64 | 333 | 323.53 | 93 | 40 | 63 | 7.00 | 5.60 | |

| 54 | 226 | 218.42 | 73 | 32 | 48 | 2.90 | 2.00 | 65 | 338 | 328.58 | 93 | 40 | 63 | 7.40 | 5.75 | |

| 60 | 250 | 242.66 | 73 | 32 | 48 | 3.40 | 2.60 | 68 | 353 | 343.74 | 93 | 40 | 63 | 7.94 | 6.32 | |

| 65 | 270 | 262.87 | 83 | 32 | 55 | 4.10 | 3.00 | 70 | 363 | 353.84 | 93 | 40 | 63 | 8.30 | 6.70 | |

| 70 | 290 | 283.07 | 83 | 32 | 55 | 4.57 | 3.50 | 72 | 373 | 363.94 | 93 | 40 | 63 | 8.80 | 7.05 | |

| 72 | 299 | 291.16 | 83 | 32 | 55 | 4.80 | 3.70 | 75 | 388 | 379.1 | 93 | 40 | 63 | 9.35 | 7.70 | |

| 75 | 311 | 303.28 | 83 | 32 | 55 | 5.10 | 4.00 | 80 | 414 | 404.36 | 98 | 45 | 66 | 10.50 | 8.70 | |

| 80 | 331 | 323.49 | 88 | 35 | 60 | 5.90 | 4.60 | 85 | 439 | 429.62 | 98 | 45 | 66 | 12.00 | 10.20 | |

| 85 | 351 | 343.69 | 88 | 35 | 60 | 6.50 | 5.20 | 90 | 464 | 454.88 | 98 | 45 | 66 | 13.20 | 11.00 | |

| 90 | 371 | 363.9 | 88 | 35 | 60 | 7.15 | 5.80 | |||||||||

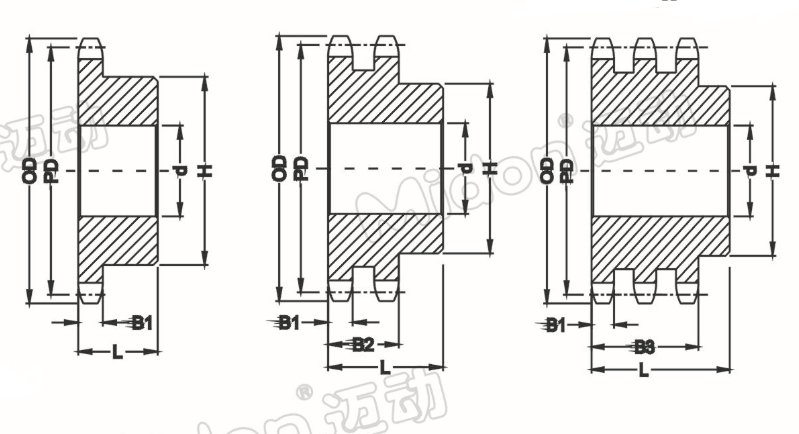

| 链轮排齿参数(美标、欧标) | |||||||||||||||

| 美标 | |||||||||||||||

| 链轮号 | 节距 | 滚子直径 | 齿节高 | 倒角高 | 倒角宽 | 弧半径 | 齿厚(1~4排) | 齿幅(2~3排) | 齿幅(4排) | 排距 | |||||

| SPROCKET NO: | pitch | Roller Dia | h | A | C | R | T1 | T2/T3 | T4 | B2 | B3 | B2 | B3 | B4 | Pt |

| 25 | 6.35 | 3.30 | 4.0 | 3.2 | 0.8 | 6.8 | 2.8 | 2.7 | 2.4 | 9.1 | 15.3 | 8.8 | 15.2 | 21.6 | 6.4 |

| 35 | 9.525 | 5.80 | 5.0 | 4.8 | 1.2 | 10.2 | 4.3 | 4.1 | 3.8 | 14.2 | 24.4 | 13.9 | 24 | 34.1 | 10.1 |

| 41 | 12.70 | 7.77 | 7.0 | 7.0 | 1.1 | 19.2 | 2.8 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 |

| 40 | 12.70 | 7.92 | 7.0 | 6.4 | 1.6 | 13.5 | 7.2 | 7.0 | 6.5 | 21.4 | 35.8 | 20.9 | 35.3 | 49.7 | 14.4 |

| 50 | 15.875 | 10.16 | 10.3 | 7.9 | 2.0 | 16.9 | 8.7 | 8.4 | 7.9 | 26.5 | 44.6 | 26 | 44.1 | 62.2 | 18.1 |

| 60 | 19.05 | 11.91 | 11.8 | 9.5 | 2.4 | 20.3 | 11.7 | 11.3 | 10.6 | 34.1 | 56.9 | 33.4 | 56.2 | 79.0 | 7.0 |

| 80 | 25.40 | 15.88 | 15.5 | 12.7 | 3.2 | 27.0 | 14.5 | 14.1 | 13.1 | 43.4 | 72.7 | 42.6 | 71.9 | 101.2 | 29.3 |

| 100 | 31.75 | 19.05 | 19.2 | 15.9 | 4.0 | 33.8 | 17.5 | 17.0 | 16.0 | 52.8 | 88.6 | 51.8 | 87.6 | 123.4 | 35.8 |

| 120 | 38.10 | 22.22 | 23.0 | 19.1 | 4.8 | 40.5 | 23.5 | 22.7 | 21.5 | 68.1 | 113.5 | 66.9 | 112.3 | 157.7 | 45.4 |

| 140 | 44.45 | 25.40 | 27.0 | 22.2 | 5.6 | 47.2 | 23.5 | 22.7 | 21.5 | 71.6 | 120.5 | 70.4 | 119.3 | 168.3 | 48.9 |

| 160 | 50.80 | 28.58 | 31.6 | 25.4 | 6.4 | 54.0 | 29.3 | 28.4 | 27.0 | 86.9 | 145.4 | 85.5 | 144 | 202.5 | 58.5 |

| 180 | 57.15 | 35.71 | 36.8 | 28.5 | 7.2 | 61.0 | 33.1 | 32.0 | 30.4 | 97.8 | 163.6 | 96.2 | 162 | 227.8 | 65.8 |

| 200 | 63.50 | 39.67 | 39.6 | 31.8 | 7.9 | 67.5 | 35.5 | 34.1 | 32.5 | 105.7 | 177.3 | 104.1 | 175.7 | 247.3 | 71.6 |

| 240 | 76.20 | 47.62 | 48.5 | 38.1 | 9.5 | 81.0 | 44.1 | 42.7 | 40.7 | 130.5 | 218.3 | 128.5 | 216.3 | 304.1 | 87.8 |

| 欧标(A、B系列链轮主要参数) | |||||||||||||||

| 链轮号 | 节距 | 滚子直径 | 齿节高 | 倒角高 | 倒角宽 | 弧半径 | 齿厚(1~4排) | 齿幅(2~4排) | 排距 | ||||||

| SPROCKET NO: | pitch | Roller Dia | h | A | C | R | T1 | T2/T3 | T4 | B2 | B3 | B4 | Pt | ||

| 4B | 6 | 4 | 4.1 | 3 | 0.6 | 6 | 2.6 | 2.5 | 2.4 | 一 | 一 | 一 | 一 | ||

| 5B | 8 | 5 | 5.3 | 4 | 0.8 | 8 | 2.8 | 2.7 | 2.6 | 8.3 | 13.9 | 19.4 | 5.6 | ||

| 6B | 9.525 | 6.35 | 6.2 | 4.8 | 1 | 10 | 5.3 | 5.2 | 5.0 | 15.4 | 25.6 | 35.6 | 10.2 | ||

| 8B | 12.70 | 8.51 | 8.4 | 6.4 | 1.3 | 13 | 7.2 | 7.0 | 6.8 | 21.0 | 34.9 | 48.5 | 13.9 | ||

| 10B | 15.88 | 10.16 | 10.2 | 7.9 | 1.6 | 16 | 9.1 | 9.0 | 9.0 | 25.6 | 42.2 | 58.8 | 16.6 | ||

| 12B | 19.05 | 12.07 | 11.2 | 9.5 | 2 | 19 | 11.1 | 10.8 | 10.9 | 30.4 | 49.9 | 69.4 | 19.5 | ||

| 16B | 25.40 | 15.88 | 14.6 | 12.7 | 2.5 | 26 | 16.2 | 15.8 | 15.8 | 47.7 | 79.6 | 111.5 | 30.9 | ||

| 20B | 31.75 | 19.05 | 18.0 | 15.9 | 3.5 | 32 | 18.5 | 18.2 | 18.2 | 54.6 | 91.0 | 127.5 | 36.5 | ||

| 24B | 38.10 | 25.40 | 22.4 | 19.1 | 4 | 38 | 24.1 | 23.6 | 23.6 | 72.0 | 120.3 | 168.7 | 48.4 | ||

| 28B | 44.45 | 27.94 | 24.9 | 22.2 | 5 | 44 | 29.4 | 28.8 | 28.8 | 88.4 | 148.0 | 207.6 | 59.6 | ||

| 32B | 50.80 | 29.21 | 28.2 | 25.4 | 6 | 51 | 29.4 | 28.8 | 28.8 | 87.4 | 146.0 | 204.6 | 58.6 | ||

| 40B | 63.50 | 39.37 | 34.9 | 31.8 | 8 | 64 | 36.2 | 35.4 | 35.4 | 107.7 | 180.0 | 252.3 | 72.3 | ||

| 48B | 76.20 | 48.26 | 41.8 | 38.1 | 9 | 76 | 43.3 | 42.5 | 42.5 | 133.7 | 224.9 | 316.1 | 91.2 | ||

| 56B | 88.90 | 53.98 | 50.2 | 44.5 | 11 | 89 | 50.7 | 49.6 | 49.6 | 156.2 | 262.8 | 369.4 | 106.6 | ||

| 64B | 101.60 | 63.50 | 57.8 | 50.8 | 13 | 102 | 57.9 | 56.7 | 56.7 | 176.6 | 296.5 | 416.4 | 119.9 | ||

| 72B | 114.30 | 72.39 | 66.0 | 57.2 | 15 | 114 | 65.2 | 63.8 | 63.8 | 200.1 | 336.4 | 472.7 | 136.3 | ||

链轮的安装要求:

1、根据规范精确选用传动链轮类型。

2、按精确方法将主、从动链轮设备到位,且拧紧紧固件使其到达规矩力矩恳求。

3、装上传动链条并调整好松紧度后,检查链条与链轮配合是不是顺利、共面,且与链罩无干与。

4、检查设备传动链轮的方位(变速器输出副轴、轮毂等)情况是不是杰出,否则须维修或更换有关件。

链轮使用过程中的注意事项:

1、从动链轮应有防松方法与措施。

2、链轮和链条最好一起更换,若只更换其中之一,会加剧两头的磨损。

3、要守时地清洗及光滑传动链条、传动链轮,以前进其运用寿命。

4、从动链轮装车后,应使用调节器和后摇架刻线将后轮轴调正,这么既可避免后轮跑偏,也能避免链轮与链条的早期磨损。

公司名称:上海迈动机电设备有限公司

公司地址:上海青浦工业区崧海路98号

邮政编码:201703

公司电话:021-54422420

公司传真:021-54422420-801

邮箱:shmidon@126.com

户名:上海迈动机电设备有限公司

税号:310112660703692

开户行:工行上海莘庄支行

账号:1001140209007024765

电话:021-54422420 54422402

传真:021-54422420-801

地址:上海莘庄工业园区申富路128号(开票)

地址:上海青浦工业园区崧海路98号(收货地址)

上海迈动机电设备有限公司提供17%的增值税发票;

品质100%保证,让你更放心使用。